Description

Lighting fixtures designed for use in health care facilities must provide effective illumination and satisfy a number of demanding lighting and environmental requirements. And Engineered Products Company (EPCO) Fixture Whips are the common thread among all of a Health Care Facility’s lighting systems.

We offer a broad variety of Health Care Fixture Whips in multiple configurations for LED (and Fluorescent) lighting systems that provide power and can integrate easily and efficiently with digital lighting controls for dimming and switching to improve building operations for virtually all health care environments.

EPCO’s Health Care Fixture Whips meet the requirements for 2023 National Electrical Code: Articles 300.3(B)(2), (C)(1), Section 725.136(I)(1), and 725.139(A through D)(1), and California Title 24 Lighting Controls, Articles 130.1(A)(B)(C)(D)(E). They are a cost-effective solution saving the contractor time and labor when compared to buying and terminating expensive MC cable or making a fixture whip solution on the job site.

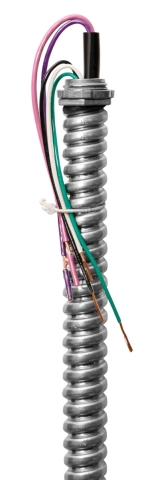

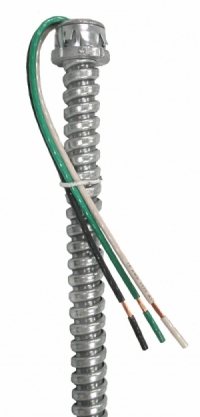

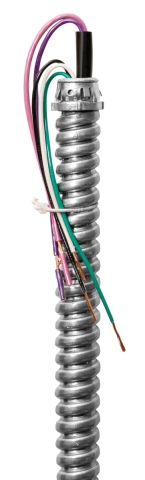

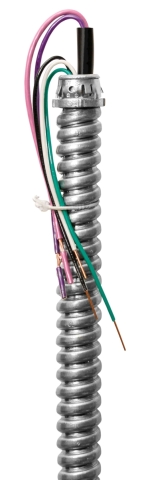

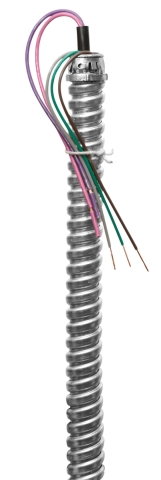

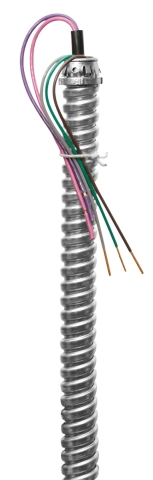

Our Standard Health Care Fixture Whip is intended to exclusively connect the line voltage conductors of an LED Luminaire’s Driver to the incoming power conductors within an electrical junction box and can be used in new or retrofit construction.

We also build “custom” Health Care Fixture Whips to your specifications in any length or wire gauge size using UL Listed components. Contact our Inside Sales Department (800.336.1976 or sales@engproducts.com) for more specific information.

TYPICAL APPLICATIONS

- Visitor and Lobby Areas

- Nurse and Reception Areas

- Patient Areas

- Corridors and Stairways

- Procedure Rooms

- MRI Imaging Lighting

- Lighting and Food Processing

- Cleanroom and Containment Lighting

- Educational Lighting

- Egress Lighting

- Parking Areas

Part Numbers

More Details

More Details

More Details

More Details

Product Spec

| HEALTH CARE FIXTURE WHIPS SPECIFICATIONS | |

| Flexible Metal Conduit | Protects the circuit conductors in all health care environments. |

| Conductors | Solid and Stranded Copper |

| Conductor Insulation | Power Conductors: THHN + Protective Polypropylene Cover Control Conductors: TFN |

| Maximum Temperature Rating | 194°F (90°C) Dry |

| Grounding Method | Includes 12 AWG green insulated copper grounding conductor per NEC 250.118(10)(b) |

| Maximum Voltage Rating | 600 Volts (all conductors) |

| Compliance Requirements | 2023 National Electrical Code: Articles 300.3(B)(2), (C)(1), Section 725.136(I)(1), and 725.139(A through D)(1), and California Title 24 Lighting Controls, Articles 130.1(A)(B)(C)(D)(E) |